Home

Home

Back

Back

Definition: A pipe flow calculator is a tool used to determine the velocity and discharge rate of water flowing through a pipe under gravity, leveraging the Hazen-Williams equation for gravity-fed systems. It calculates how water moves through pipelines based on physical properties like pipe size, length, elevation differences, and material roughness, providing insights into flow dynamics for water distribution systems.

Purpose: This calculator is essential in fluid mechanics, civil engineering, and environmental engineering for designing and analyzing water distribution networks, such as gravity-fed pipelines used in irrigation, drainage, and municipal water supply systems. It helps engineers ensure efficient water flow, minimize energy losses, and maintain system performance under varying conditions.

Practical Applications: Pipe flow calculations are critical for projects like urban water management, agricultural irrigation systems, and industrial process piping. For instance, a city planner might use it to size pipes for a new drainage system, ensuring adequate flow during heavy rainfall, while a farmer could optimize irrigation channels to reduce water waste.

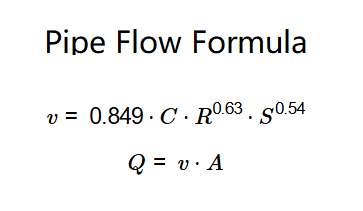

The calculator employs the Hazen-Williams equation to estimate water flow in gravity-fed pipes, which is expressed as:

Where:

Unit Conversions: To ensure accuracy, the calculator converts inputs to SI units:

Explanation: Users input the pipe’s diameter, length, height difference, and select the pipe material to determine its roughness coefficient (C). The calculator converts these values to SI units, computes the hydraulic radius and slope, applies the Hazen-Williams equation, and calculates both water velocity and discharge rate. Results are displayed in multiple units, assuming water flow at temperatures between 5–25 °C and pipe diameters ranging from 50 mm to 1850 mm for optimal accuracy.

Example: For a 200 mm diameter steel pipe (C = 120), 100 m long, with a 10 m height difference, the calculator might yield a velocity of approximately 1.5 m/s and a discharge of 0.047 m³/s (47 L/s, 12,400 gpm), depending on the exact inputs and conversions.

Significance: Pipe flow calculations are fundamental for ensuring the efficiency and reliability of water distribution systems. They enable engineers to:

Real-World Impact: For example, in a rural irrigation project, accurate pipe flow calculations can determine the optimal pipe size and slope to deliver water efficiently to fields, while in urban settings, they help design stormwater drainage systems to handle heavy rain without flooding.

Guidelines: To use this calculator effectively, follow these steps:

Tips: Ensure inputs are realistic for gravity-fed water systems operating at 5–25 °C. For pipes outside the 50–1850 mm range, results may be less accurate due to the Hazen-Williams equation’s limitations. If unsure about the roughness coefficient, consult engineering references or standards for typical values (e.g., C typically ranges from 80 to 150 for most materials).

Q: What if I enter a negative value?

A: The calculator sets results to 0 for invalid (negative or zero) inputs, as physical measurements like diameter, length, and height difference must be positive.

Q: Why does pipe material affect flow?

A: The roughness coefficient (C) reflects the pipe’s internal surface texture, which influences friction and flow resistance. Smoother materials (e.g., plastic, C = 150) allow faster flow than rougher ones (e.g., cast iron, C = 100).

Q: Can this calculator be used for other fluids?

A: No, it’s designed for water at 5–25 °C using the Hazen-Williams equation. For other fluids, use the Darcy-Weisbach or Manning’s equation, adjusted for fluid properties like viscosity and density.

Q: What is the typical roughness coefficient (C) for pipes?

A: Common values range from 80 (very rough, like old concrete) to 150 (very smooth, like new plastic). Steel, cast iron, concrete, and copper have typical C values of 120, 100, 100, and 130, respectively.

Q: How accurate are the results for large pipes?

A: The Hazen-Williams equation is most accurate for pipes 50–1850 mm in diameter carrying water at 5–25 °C. For larger or smaller pipes, or different temperatures, results may require adjustment or alternative methods like Darcy-Weisbach.