Home

Home

Back

Back

Definition: The Upper and Lower Control Limit Calculator computes the upper control limit (UCL) and lower control limit (LCL) for a process dataset, using the mean, standard deviation, and control limit factor.

Purpose: This tool helps monitor process stability in statistical process control (SPC), identifying whether variations are due to common or special causes, useful in manufacturing, healthcare, and quality assurance.

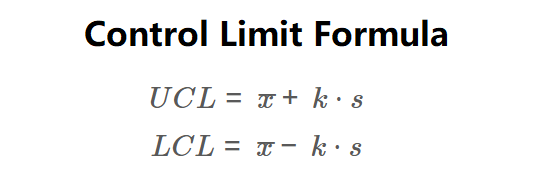

The calculator uses the following formulas:

\( UCL = \bar{x} + k \cdot s \)

\( LCL = \bar{x} - k \cdot s \)

Where:

Steps:

Calculating control limits is essential for:

Example: Calculate control limits for a coffee shop monitoring espresso shot brewing times with a mean of 25.45 seconds, standard deviation of 0.943 seconds, and a control limit factor of 3:

Q: What are control limits?

A: Control limits are statistical boundaries (UCL and LCL) that define the acceptable range of variation in a process, distinguishing between common and special cause variations.

Q: Why use a three-sigma limit?

A: A three-sigma limit (k=3) covers 99.73% of data in a normal distribution, balancing sensitivity and stability for process monitoring.

Q: How do control limits differ from specification limits?

A: Control limits are statistically derived from process data, while specification limits are set based on customer requirements or standards.