Rod Diameter Calculator - Axial Load Effect

Unit Converter ▲

Unit Converter ▼

1. What is the Rod Diameter Calculator?

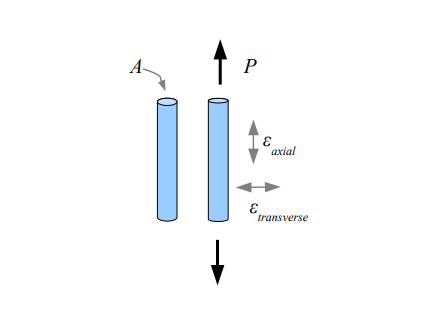

Definition: The Rod Diameter Calculator determines the initial and final diameter of a rod under an axial tensile load, including the change in diameter, accounting for axial and transverse strain using Poisson's ratio.

Purpose: Helps engineers analyze dimensional changes in rods due to loading.

Reference:Applied Strength of Materials for Engineering Technology

http://www.etcs.pfw.edu/~dupenb/ET_200/Applied%20Str%20of%20Mat%20for%20ET%20v14%20July%202018.pdf

2. How Does the Calculator Work?

Formula:

\( A = \frac{\pi d^2}{4} \), \( \epsilon_{long} = \frac{P}{A \cdot E} \), \( \epsilon_{transverse} = -\nu \cdot \epsilon_{long} \), \( \delta_{transverse} = \epsilon_{transverse} \cdot d_i \), \( d_f = d_i + \delta_{transverse} \)

Where:

- \(A\): Cross-sectional area (in²)

- \(d_i\): Initial diameter (in)

- \(P\): Load (lb)

- \(E\): Young's modulus (psi)

- \(\nu\): Poisson's ratio

- \(\epsilon_{long}\): Axial strain

- \(\epsilon_{transverse}\): Transverse strain

- \(\delta_{transverse}\): Change in diameter (in)

- \(d_f\): Final diameter (in)

Steps:

- Step 1: Input Initial Area. Enter the cross-sectional area (e.g., 0.19635 in²).

- Step 2: Input Load. Enter the axial load (e.g., 6000 lb).

- Step 3: Input Young's Modulus. Enter the material's modulus (e.g., 10×10⁶ psi).

- Step 4: Select or Input Poisson's Ratio. Choose a material (Steel: 0.25, Aluminum: 0.33, Concrete: 0.10-0.20 avg 0.15) or enter a custom value.

- Step 5: Calculate. The calculator computes initial diameter, change in diameter, and final diameter in both inches and centimeters.

3. Importance of Diameter Calculation

Calculating diameter changes is crucial for:

- Material Deformation: Ensures the rod's dimensional stability under load.

- Design Safety: Helps determine if the rod meets design specifications.

- Unit Consistency: Supports conversions across units.

4. Using the Calculator

Example:

Area = 0.19635 in², Load = 6000 lb, Young's Modulus = 10×10⁶ psi, Poisson's Ratio = 0.33 (Aluminum):

- Step 1: \( d_i = \sqrt{\frac{4 \cdot 0.19635}{\pi}} \approx 0.50000 \, \text{in} = 1.27000 \, \text{cm} \).

- Step 2: \( \epsilon_{long} = \frac{6000}{0.19635 \cdot 10^7} \approx 0.000306 \).

- Step 3: \( \epsilon_{transverse} = -0.33 \cdot 0.000306 \approx -0.00101 \).

- Step 4: \( \delta_{transverse} = -0.00101 \cdot 0.50000 \approx -0.000504 \, \text{in} = -0.001280 \, \text{cm} \).

- Step 5: \( d_f = 0.50000 - 0.000504 \approx 0.49950 \, \text{in} = 1.26881 \, \text{cm} \).

5. Frequently Asked Questions (FAQ)

Q: What is Poisson's ratio?

A: Poisson's ratio is the ratio of transverse strain to axial strain under elastic deformation.

Q: Can I use metric units?

A: Yes, the calculator converts mm² and kN to in² and lb internally, and displays diameters in both in and cm.

Q: Is this accurate for all materials?

A: Yes, if material properties (E, ν) are correctly input.

Home

Home

Back

Back