1. What is Principal Stress Calculator?

Definition: This calculator computes the maximum and minimum principal stresses (\( \sigma_{\text{max}} \), \( \sigma_{\text{min}} \)), the angle of principal stress (\( \theta \)), and the maximum and minimum angles of shear stress (\( \theta_{\tau_{\text{max}}} \), \( \theta_{\tau_{\text{min}}} \)) for a 2D stress state.

Purpose: It is used in engineering and material science to analyze the stress state of a material, determine the directions of maximum and minimum stresses, and identify the orientations of maximum shear stress, which are critical for failure analysis and design.

2. How Does the Calculator Work?

The calculator uses the following formulas:

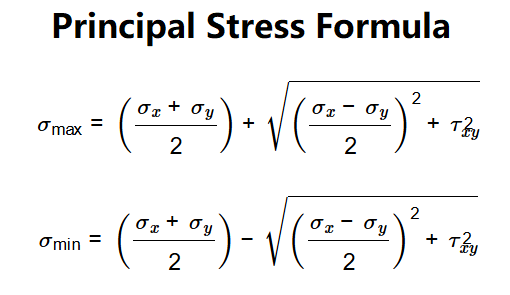

Formulas:

- Maximum Principal Stress: \[

\sigma_{\text{max}} = \left( \frac{\sigma_x + \sigma_y}{2} \right) + \sqrt{ \left( \frac{\sigma_x - \sigma_y}{2} \right)^2 + \tau_{xy}^2 }

\]

- Minimum Principal Stress: \[

\sigma_{\text{min}} = \left( \frac{\sigma_x + \sigma_y}{2} \right) - \sqrt{ \left( \frac{\sigma_x - \sigma_y}{2} \right)^2 + \tau_{xy}^2 }

\]

- Angle of Principal Stress: \[

\theta = \frac{1}{2} \arctan \left( \frac{2 \tau_{xy}}{\sigma_x - \sigma_y} \right)

\]

- Maximum Angle of Shear Stress: \[

\theta_{\tau_{\text{max}}} = \theta + 45^\circ

\]

- Minimum Angle of Shear Stress: \[

\theta_{\tau_{\text{min}}} = \theta - 45^\circ

\]

Where:

- \( \sigma_{\text{max}} \): Maximum principal stress (GPa, MPa, Pa, psi)

- \( \sigma_{\text{min}} \): Minimum principal stress (GPa, MPa, Pa, psi)

- \( \theta \): Angle of principal stress (degrees, radians)

- \( \theta_{\tau_{\text{max}}} \): Maximum angle of shear stress (degrees, radians)

- \( \theta_{\tau_{\text{min}}} \): Minimum angle of shear stress (degrees, radians)

- \( \sigma_x \): Normal stress in x-direction (GPa, MPa, Pa, psi)

- \( \sigma_y \): Normal stress in y-direction (GPa, MPa, Pa, psi)

- \( \tau_{xy} \): Shear stress (GPa, MPa, Pa, psi)

Unit Conversions:

- Stress (\( \sigma_x \), \( \sigma_y \), \( \tau_{xy} \), \( \sigma_{\text{max}} \), \( \sigma_{\text{min}} \)):

- 1 GPa = 1 GPa

- 1 MPa = 10⁻³ GPa

- 1 Pa = 10⁻⁹ GPa

- 1 psi = 6.89476 × 10⁻³ GPa

- Angle (\( \theta \), \( \theta_{\tau_{\text{max}}} \), \( \theta_{\tau_{\text{min}}} \)):

- 1 degree = 1 degree

- 1 radian = 57.2958 degrees

Steps:

- Enter the normal stresses (\( \sigma_x \), \( \sigma_y \)) and shear stress (\( \tau_{xy} \)) with their respective units.

- Convert all stresses to GPa for calculation.

- Calculate the maximum and minimum principal stresses (\( \sigma_{\text{max}} \), \( \sigma_{\text{min}} \)).

- Calculate the angle of principal stress (\( \theta \)).

- Calculate the maximum and minimum angles of shear stress (\( \theta_{\tau_{\text{max}}} \), \( \theta_{\tau_{\text{min}}} \)).

- Convert the results to the selected units.

- Display the results with 4 decimal places.

3. Importance of Principal Stress Calculation

Calculating principal stresses and their orientations is crucial for:

- Failure Analysis: Identifying the maximum and minimum stresses to predict material failure using criteria like the von Mises or Tresca yield criteria.

- Structural Design: Ensuring that components can withstand the maximum stresses and shear stresses in critical directions.

- Material Testing: Understanding the stress state of a material under complex loading conditions to evaluate its mechanical behavior.

4. Using the Calculator

Example:

Calculate the principal stresses and their orientations for a stress state with \( \sigma_x = 100 \, \text{MPa} \), \( \sigma_y = 40 \, \text{MPa} \), and \( \tau_{xy} = 30 \, \text{MPa} \).

- Enter the normal stress in x-direction, \( \sigma_x = 100 \, \text{MPa} \).

- Enter the normal stress in y-direction, \( \sigma_y = 40 \, \text{MPa} \).

- Enter the shear stress, \( \tau_{xy} = 30 \, \text{MPa} \).

- The calculator computes:

- Convert to GPa: \( \sigma_x = 0.1 \, \text{GPa} \), \( \sigma_y = 0.04 \, \text{GPa} \), \( \tau_{xy} = 0.03 \, \text{GPa} \).

- Maximum Principal Stress: \[

\sigma_{\text{max}} = \left( \frac{0.1 + 0.04}{2} \right) + \sqrt{ \left( \frac{0.1 - 0.04}{2} \right)^2 + (0.03)^2 } = 0.07 + \sqrt{ (0.03)^2 + (0.03)^2 } = 0.1124 \, \text{GPa} = 112.4 \, \text{MPa}

\]

- Minimum Principal Stress: \[

\sigma_{\text{min}} = \left( \frac{0.1 + 0.04}{2} \right) - \sqrt{ \left( \frac{0.1 - 0.04}{2} \right)^2 + (0.03)^2 } = 0.07 - \sqrt{ (0.03)^2 + (0.03)^2 } = 0.0276 \, \text{GPa} = 27.6 \, \text{MPa}

\]

- Angle of Principal Stress: \[

\theta = \frac{1}{2} \arctan \left( \frac{2 \times 0.03}{0.1 - 0.04} \right) = \frac{1}{2} \arctan(1) = 22.5^\circ

\]

- Maximum Angle of Shear Stress: \[

\theta_{\tau_{\text{max}}} = 22.5^\circ + 45^\circ = 67.5^\circ

\]

- Minimum Angle of Shear Stress: \[

\theta_{\tau_{\text{min}}} = 22.5^\circ - 45^\circ = -22.5^\circ

\]

5. Frequently Asked Questions (FAQ)

Q: What are principal stresses?

A: Principal stresses are the maximum and minimum normal stresses acting on a material at a point, occurring on planes where the shear stress is zero.

Q: Why are the maximum shear stress planes at 45° to the principal planes?

A: In a 2D stress state, the maximum shear stress occurs at 45° to the principal stress directions because the shear stress is maximized when the normal stresses are averaged, which happens at this angle.

Q: How are principal stresses used in real life?

A: They are used in engineering to predict material failure, design safe structures, and analyze stress states in components under complex loading, such as in bridges, aircraft, and machinery.

Principal Stress Calculator© - All Rights Reserved 2025

Home

Home

Back

Back