LPM to PSI Conversion Relationship

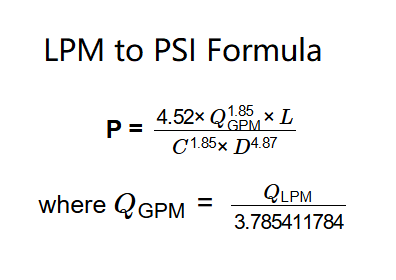

The pressure loss (PSI) due to flow rate (LPM) in a pipe can be calculated using the Hazen-Williams formula, adjusted for LPM. The formula is as follows:

P = \( \frac{4.52 \times Q_{\text{GPM}}^{1.85} \times L}{C^{1.85} \times D^{4.87}} \), where \( Q_{\text{GPM}} = \frac{Q_{\text{LPM}}}{3.785411784} \)

Where:

- P = Pressure loss (PSI)

- QLPM = Flow rate (Liters per Minute, LPM)

- QGPM = Flow rate (Gallons per Minute, GPM), calculated as QGPM = QLPM / 3.785411784

- L = Pipe length (feet)

- C = Hazen-Williams coefficient (depends on pipe material)

- D = Pipe diameter (inches)

This formula helps determine the pressure loss in a pipe system based on the flow rate, pipe dimensions, and material properties.

Input Parameters:

- Flow Rate: Volume of fluid per unit time (e.g., LPM, LPH, L/s, m³/h, GPM).

- Pipe Length: Length of the pipe (m or ft).

- Pipe Diameter: Inner diameter of the pipe (mm or in).

- Hazen-Williams Coefficient (C): Depends on pipe material:

- Asbestos-cement: 140

- Cast iron new: 130

- Cast iron 10 years: 113

- Cast iron 20 years: 100

- Cement-Mortar Lined Ductile Iron: 140

- Concrete: 140

- Copper: 140

- Steel: 120

- Galvanized iron: 120

- Polyethylene: 140

- Polyvinyl chloride (PVC): 150

- Fibre-reinforced plastic (FRP): 150

- Custom: User-defined (50-200)

Practical Applications

This calculator is useful in:

- Plumbing: Estimate pressure drop in water supply lines.

- Irrigation: Calculate pressure loss for sprinkler systems.

- Engineering: Design piping systems with acceptable pressure losses.

Example Calculation

Let’s calculate the pressure loss for a flow rate of 0.01 LPM, a pipe length of 10 meters, a pipe diameter of 100 mm, and a PVC pipe (C = 150).

Step 1: Convert Flow Rate to GPM

Convert 0.01 LPM to GPM using the conversion factor 1 LPM ≈ 0.264172 GPM:

\[ Q_{\text{GPM}} = \frac{0.01}{3.785411784} \approx 0.002641 \, \text{GPM} \]

Step 2: Convert Pipe Length to Feet

Convert 10 meters to feet using 1 m = 3.28084 ft:

\[ L = 10 \times 3.28084 = 32.8084 \, \text{ft} \]

Step 3: Convert Pipe Diameter to Inches

Convert 100 mm to inches using 1 mm = 0.0393701 in:

\[ D = \frac{100}{25.4} \approx 3.937 \, \text{in} \]

Step 4: Calculate Pressure Loss (PSI)

Apply the Hazen-Williams formula:

\[ P = \frac{4.52 \times Q_{\text{GPM}}^{1.85} \times L}{C^{1.85} \times D^{4.87}} \]

Substitute the values (\( Q_{\text{GPM}} = 0.002641 \), \( L = 32.8084 \), \( C = 150 \), \( D = 3.937 \)):

\[ P = \frac{4.52 \times 0.002641^{1.85} \times 32.8084}{150^{1.85} \times 3.937^{4.87}} \approx 0.000038 \, \text{PSI} \]

Displayed as: 3.80E-5 PSI (using scientific notation for small values).

Step 5: Convert to Other Units

Convert PSI to bar (1 PSI = 0.0689475729 bar) and kPa (1 PSI = 6.89475729 kPa):

- Bar: \( 0.000038 \times 0.0689475729 \approx 0.00000262 \, \text{bar} \), displayed as 2.62E-6 bar

- kPa: \( 0.000038 \times 6.89475729 \approx 0.000262 \, \text{kPa} \), displayed as 2.62E-4 kPa

Conversion Constants

Key conversion factors:

- 1 Liter = 0.264172 Gallons

- 1 m = 3.28084 ft

- 1 mm = 0.0393701 in

- 1 PSI = 0.0689475729 bar = 6.89475729 kPa

Home

Home

Back

Back