1. What is a Valve and Fitting Pressure Loss Calculator?

Definition: This calculator computes the pressure loss (\( \Delta P \)) due to valves and fittings in a pipe system, using a loss coefficient \( K \).

Purpose: It is used in fluid dynamics and HVAC design to quantify pressure losses caused by fittings, aiding in pipe system design and pump selection.

2. How Does the Calculator Work?

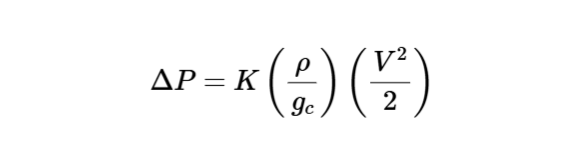

The calculator uses the following formula for pressure loss:

Pressure Loss:

\[

\Delta P = K \left( \frac{\rho}{g_c} \right) \left( \frac{V^2}{2} \right)

\]

Where:

- \( \Delta P \): Pressure loss (lb_f/ft², Pa)

- \( K \): Geometry and size-dependent loss coefficient (dimensionless)

- \( \rho \): Fluid density (lb_m/ft³, kg/m³)

- \( g_c \): Units conversion factor (ft-lb_m/lb_f-sec², m-kg/N-s²)

- \( V \): Average velocity (fps, m/s)

Unit Conversions:

- Fluid Density (\( \rho \)): lb_m/ft³, kg/m³ (1 kg/m³ = 0.062428 lb_m/ft³)

- Velocity (\( V \)): fps, m/s (1 m/s = 3.28084 fps)

- Conversion Factor (\( g_c \)): ft-lb_m/lb_f-sec², m-kg/N-s² (1 m-kg/N-s² = 3.28084 ft-lb_m/lb_f-sec²)

- Pressure Loss (\( \Delta P \)): lb_f/ft², Pa (1 lb_f/ft² = 47.8803 Pa)

Steps:

- Enter the loss coefficient (\( K \)), fluid density (\( \rho \)), average velocity (\( V \)), and conversion factor (\( g_c \)), and select their units.

- Convert \( \rho \), \( V \), and \( g_c \) to lb_m/ft³, fps, and ft-lb_m/lb_f-sec², respectively.

- Calculate the pressure loss using the formula.

- Convert the result to the selected unit (lb_f/ft² or Pa).

- Display the result with 5 decimal places, or in scientific notation if the value is greater than 10,000 or less than 0.00001.

3. Importance of Valve and Fitting Pressure Loss Calculation

Calculating pressure loss due to valves and fittings is crucial for:

- Pipe System Design: Accounts for additional pressure losses to ensure proper pipe sizing and pump requirements.

- Energy Efficiency: Minimizes energy consumption by optimizing system components to reduce losses.

- System Performance: Ensures adequate fluid flow for industrial, HVAC, or plumbing applications.

4. Using the Calculator

Examples:

- Example 1: For \( K = 1.5 \), \( \rho = 62.4 \, \text{lb_m/ft³} \), \( V = 4 \, \text{fps} \), \( g_c = 32.2 \, \text{ft-lb_m/lb_f-sec²} \), pressure loss in lb_f/ft²:

- \( \Delta P = 1.5 \times \left( \frac{62.4}{32.2} \right) \times \left( \frac{4^2}{2} \right) \approx 1.5 \times 1.93789 \times 8 \approx 23.26 \)

- Since 23.26 < 10000 and > 0.00001, display with 5 decimal places: \( 23.26000 \)

- Example 2: For \( K = 2.0 \), \( \rho = 1000 \, \text{kg/m³} \), \( V = 1.2 \, \text{m/s} \), \( g_c = 1 \, \text{m-kg/N-s²} \), pressure loss in Pa:

- Convert: \( \rho = 1000 \times 0.062428 \approx 62.428 \, \text{lb_m/ft³} \)

- \( V = 1.2 \times 3.28084 \approx 3.93701 \, \text{fps} \)

- \( g_c = 1 \times 3.28084 \approx 3.28084 \, \text{ft-lb_m/lb_f-sec²} \)

- \( \Delta P = 2.0 \times \left( \frac{62.428}{3.28084} \right) \times \left( \frac{3.93701^2}{2} \right) \approx 2.0 \times 19.036 \times 7.749 \approx 294.77 \, \text{lb_f/ft²} \)

- Convert to Pa: \( 294.77 \times 47.8803 \approx 14111.5 \)

- Since 14111.5 > 10000, display in scientific notation: \( 1.41115 \times 10^4 \)

- Example 3: For \( K = 0.8 \), \( \rho = 60 \, \text{lb_m/ft³} \), \( V = 5 \, \text{fps} \), \( g_c = 32.2 \, \text{ft-lb_m/lb_f-sec²} \), pressure loss in lb_f/ft²:

- \( \Delta P = 0.8 \times \left( \frac{60}{32.2} \right) \times \left( \frac{5^2}{2} \right) \approx 0.8 \times 1.86335 \times 12.5 \approx 18.63 \)

- Since 18.63 < 10000 and > 0.00001, display with 5 decimal places: \( 18.63000 \)

5. Frequently Asked Questions (FAQ)

Q: What does valve and fitting pressure loss represent?

A: Pressure loss (\( \Delta P \)) quantifies the reduction in fluid pressure caused by flow through valves and fittings, impacting system efficiency.

Q: How can I determine the input parameters?

A: The loss coefficient (\( K \)) is obtained from tables based on the type and size of the valve or fitting (e.g., 1.5 for a typical elbow). Fluid density (\( \rho \)) is determined from fluid properties. Average velocity (\( V \)) is calculated from flow rate and pipe area. The conversion factor (\( g_c \)) is typically 32.2 ft-lb_m/lb_f-sec² in US units or 1 m-kg/N-s² in SI units.

Q: Why is valve and fitting pressure loss important in pipe system design?

A: It ensures accurate accounting of pressure losses for proper pump sizing and system performance optimization.

Valve and Fitting Pressure Loss Calculator© - All Rights Reserved 2025

Home

Home

Back

Back