1. What is a Leaving Air Temperature for Duct Calculator?

Definition: This calculator computes the temperature of air leaving a rectangular duct (\( T_l \)) based on the entering air temperature, surrounding air temperature, and a dimensionless parameter \( y \), calculated using the air flow rate, duct dimensions, and standard air specific heat (\( C_p = 0.24 \, \text{Btu/lb_f-°F} \)).

Purpose: It is used in HVAC design to determine the outlet air temperature of a duct, accounting for heat transfer through duct walls, aiding in system performance and thermal comfort.

2. How Does the Calculator Work?

The calculator uses the following formulas for rectangular ducts:

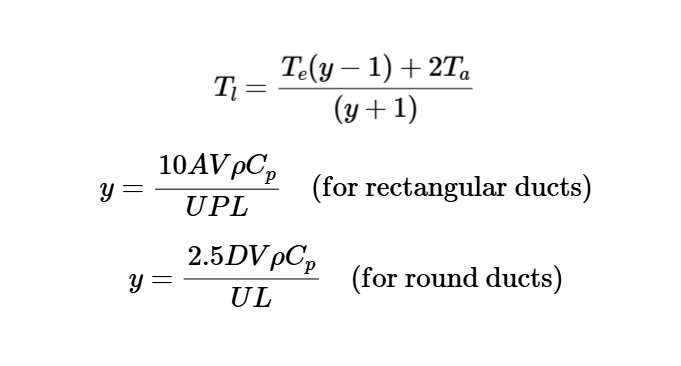

Leaving Air Temperature:

\[

T_l = \frac{T_e (y - 1) + 2 T_a}{(y + 1)}

\]

Dimensionless Constant:

\[

y = \frac{10 A V \rho C_p}{U P L}, \quad A = W \times H, \quad P = 2(W + H), \quad V = \frac{144 Q}{A}

\]

Specific Heat: \( C_p = 0.24 \, \text{Btu/lb_f-°F} \)

Where:

- \( T_l \): Temperature of air leaving duct (°F, °C)

- \( T_e \): Temperature of air entering duct (°F, °C)

- \( T_a \): Temperature of air surrounding duct (°F, °C)

- \( y \): Dimensionless constant

- \( A \): Cross-sectional area of duct (in²)

- \( W \): Width of rectangular duct (in., ft, m)

- \( H \): Height of rectangular duct (in., ft, m)

- \( P \): Perimeter of rectangular duct (in.)

- \( Q \): Air flow rate (cfm, m³/s)

- \( V \): Average velocity (fpm)

- \( \rho \): Air density (lb_f/ft³, kg/m³)

- \( C_p \): Specific heat of air (0.24 Btu/lb_f-°F)

- \( U \): Overall heat transfer coefficient (Btu/hr-ft²-°F, W/m²-K)

- \( L \): Duct length (ft, m)

Unit Conversions:

- Temperatures (\( T_e \), \( T_a \), \( T_l \)): °F, °C (°F = °C × 9/5 + 32)

- Heat Transfer Coefficient (\( U \)): Btu/hr-ft²-°F, W/m²-K (1 W/m²-K = 0.176110 Btu/hr-ft²-°F)

- Air Flow Rate (\( Q \)): cfm, m³/s (1 m³/s = 2118.88 cfm)

- Air Density (\( \rho \)): lb_f/ft³, kg/m³ (1 kg/m³ = 0.062428 lb_f/ft³)

- Duct Length (\( L \)): ft, m (1 m = 3.28084 ft)

- Width (\( W \)), Height (\( H \)):

- in.: No conversion

- ft: 1 ft = 12 in.

- m: 1 m = 39.3701 in.

Steps:

- Enter the entering air temperature (\( T_e \)), surrounding air temperature (\( T_a \)), overall heat transfer coefficient (\( U \)), air flow rate (\( Q \)), air density (\( \rho \)), duct length (\( L \)), duct width (\( W \)), and duct height (\( H \)).

- Convert all inputs to consistent units (e.g., °F, Btu/hr-ft²-°F, cfm, lb_f/ft³, in., ft).

- Calculate the cross-sectional area (\( A = W \times H \)) and perimeter (\( P = 2(W + H) \)).

- Calculate the average velocity (\( V = \frac{144 Q}{A} \)).

- Calculate the dimensionless constant (\( y \)) using \( C_p = 0.24 \, \text{Btu/lb_f-°F} \).

- Calculate the leaving air temperature (\( T_l \)).

- Display \( A \), \( P \), \( V \), \( y \), and \( T_l \) with 5 decimal places, or in scientific notation if the value is greater than 10,000 or less than 0.00001.

3. Importance of Leaving Air Temperature Calculation

Calculating the leaving air temperature is crucial for:

- HVAC System Design: Determines the outlet air temperature to ensure it meets design requirements, optimizing system performance.

- Energy Efficiency: Helps design ducts to minimize unwanted heat transfer, reducing energy consumption.

- Thermal Comfort: Ensures delivered air temperature provides occupant comfort.

4. Using the Calculator

Examples:

- Example 1: For \( T_e = 131.10 \, \text{°F} \), \( T_a = 40 \, \text{°F} \), \( W = 36 \, \text{in.} \), \( H = 24 \, \text{in.} \), \( Q = 5184 \, \text{cfm} \), \( \rho = 0.075 \, \text{lb_f/ft³} \), \( U = 0.73 \, \text{Btu/hr-ft²-°F} \), \( L = 40 \, \text{ft} \), leaving air temperature in °F:

- \( A = 36 \times 24 = 864 \, \text{in²} \)

- \( P = 2 \times (36 + 24) = 120 \, \text{in.} \)

- \( V = \frac{144 \times 5184}{864} = 864 \, \text{fpm} \)

- \( y = \frac{10 \times 864 \times 864 \times 0.075 \times 0.24}{0.73 \times 120 \times 40} \approx 38.33 \)

- \( T_l = \frac{131.10 \times (38.33 - 1) + 2 \times 40}{38.33 + 1} \approx \frac{4893.06 + 80}{39.33} \approx 126.43 \)

- Since all values are < 10000 and > 0.00001, display with 5 decimal places: \( A = 864.00000 \, \text{in²} \), \( P = 120.00000 \, \text{in.} \), \( V = 864.00000 \, \text{fpm} \), \( y = 38.33000 \), \( T_l = 126.43000 \)

- Example 2: For \( T_e = 55 \, \text{°C} \), \( T_a = 4.4 \, \text{°C} \), \( W = 0.9144 \, \text{m} \), \( H = 0.6096 \, \text{m} \), \( Q = 2.45 \, \text{m³/s} \), \( \rho = 1.2 \, \text{kg/m³} \), \( U = 4.1 \, \text{W/m²-K} \), \( L = 12 \, \text{m} \), leaving air temperature in °C:

- Convert: \( T_e = 55 \times 9/5 + 32 = 131 \, \text{°F} \), \( T_a = 4.4 \times 9/5 + 32 = 39.92 \, \text{°F} \)

- \( W = 0.9144 \times 39.3701 \approx 36 \, \text{in.} \), \( H = 0.6096 \times 39.3701 \approx 24 \, \text{in.} \)

- \( Q = 2.45 \times 2118.88 \approx 5191.26 \, \text{cfm} \)

- \( \rho = 1.2 \times 0.062428 \approx 0.074914 \, \text{lb_f/ft³} \)

- \( U = 4.1 \times 0.176110 \approx 0.722051 \, \text{Btu/hr-ft²-°F} \)

- \( L = 12 \times 3.28084 \approx 39.37008 \, \text{ft} \)

- \( A = 36 \times 24 = 864 \, \text{in²} \)

- \( P = 2 \times (36 + 24) = 120 \, \text{in.} \)

- \( V = \frac{144 \times 5191.26}{864} \approx 865.21 \, \text{fpm} \)

- \( y = \frac{10 \times 864 \times 865.21 \times 0.074914 \times 0.24}{0.722051 \times 120 \times 39.37008} \approx 39.44 \)

- \( T_l = \frac{131 \times (39.44 - 1) + 2 \times 39.92}{39.44 + 1} \approx \frac{5036.64 + 79.84}{40.44} \approx 126.52 \, \text{°F} \)

- Convert to °C: \( (126.52 - 32) \times 5/9 \approx 52.51 \)

- Since all values are < 10000 and > 0.00001, display with 5 decimal places: \( A = 864.00000 \, \text{in²} \), \( P = 120.00000 \, \text{in.} \), \( V = 865.21000 \, \text{fpm} \), \( y = 39.44000 \), \( T_l = 52.51000 \)

- Example 3: For \( T_e = 100 \, \text{°F} \), \( T_a = 80 \, \text{°F} \), \( W = 2 \, \text{ft} \), \( H = 1 \, \text{ft} \), \( Q = 500 \, \text{cfm} \), \( \rho = 0.08 \, \text{lb_f/ft³} \), \( U = 0.5 \, \text{Btu/hr-ft²-°F} \), \( L = 50 \, \text{ft} \), leaving air temperature in °F:

- Convert: \( W = 2 \times 12 = 24 \, \text{in.} \), \( H = 1 \times 12 = 12 \, \text{in.} \)

- \( A = 24 \times 12 = 288 \, \text{in²} \)

- \( P = 2 \times (24 + 12) = 72 \, \text{in.} \)

- \( V = \frac{144 \times 500}{288} = 250 \, \text{fpm} \)

- \( y = \frac{10 \times 288 \times 250 \times 0.08 \times 0.24}{0.5 \times 72 \times 50} \approx 7.68 \)

- \( T_l = \frac{100 \times (7.68 - 1) + 2 \times 80}{7.68 + 1} \approx \frac{668 + 160}{8.68} \approx 95.39 \)

- Since all values are < 10000 and > 0.00001, display with 5 decimal places: \( A = 288.00000 \, \text{in²} \), \( P = 72.00000 \, \text{in.} \), \( V = 250.00000 \, \text{fpm} \), \( y = 7.68000 \), \( T_l = 95.39000 \)

5. Frequently Asked Questions (FAQ)

Q: What does the leaving air temperature represent?

A: The leaving air temperature (\( T_l \)) is the temperature of air exiting a rectangular duct, calculated based on the entering air temperature and heat transfer through the duct walls.

Q: How can I determine the input parameters?

A: Entering and surrounding air temperatures (\( T_e \), \( T_a \)) are measured or estimated. Duct dimensions (\( W \), \( H \), \( L \)) are obtained from design specifications. Air flow rate (\( Q \)), density (\( \rho \)), and heat transfer coefficient (\( U \)) are measured or derived from standards. Specific heat is fixed at \( C_p = 0.24 \, \text{Btu/lb_f-°F} \).

Q: Why is the leaving air temperature important in HVAC design?

A: It ensures the HVAC system delivers air at the desired temperature, optimizing thermal comfort and energy efficiency.

Leaving Air Temperature for Duct Calculator© - All Rights Reserved 2025

Home

Home

Back

Back