Home

Home

Back

Back

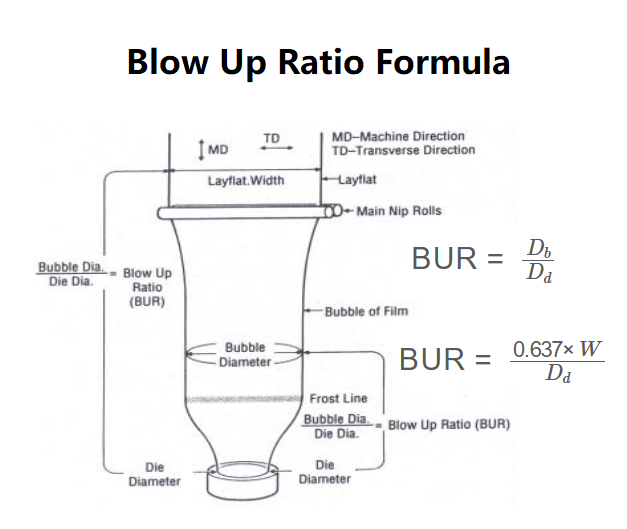

Definition: The Blow Up Ratio (BUR) Calculator determines the ratio of the bubble diameter (or final tube diameter) to the die diameter in blown film extrusion, a key parameter in plastic film manufacturing. BUR indicates the increase in the bubble diameter over the die diameter, affecting the thickness of the melt after blowing.

Purpose: Used by manufacturers in film extrusion to optimize film thickness, strength, and clarity, ensuring consistent quality in products like packaging and industrial films.

The calculator uses the following formulas, as shown in the image above:

\( \text{BUR} = \frac{D_b}{D_d} \)

\( \text{BUR} = \frac{0.637 \times W}{D_d} \)

Where:

Since it’s difficult to use calipers on the bubble to measure its thickness directly, the layflat width formula provides a more practical approach.

Steps:

The Blow Up Ratio is critical for:

Example 1: Calculate BUR using a bubble diameter of 300 mm and a die diameter of 150 mm:

Example 2: Calculate BUR using a layflat width of 471.2 mm and a die diameter of 150 mm:

Q: How accurate is the Blow Up Ratio calculation?

A: The calculation is mathematically precise using the formulas \( \text{BUR} = \frac{D_b}{D_d} \) or \( \text{BUR} = \frac{0.637 \times W}{D_d} \). Rounding errors may occur due to formatting to 4 decimal places or scientific notation for small values.

Q: Why can’t I enter negative values for diameters or width?

A: Diameters and widths must be positive as they represent physical measurements of the bubble, die, or film.

Q: Why use layflat width instead of bubble diameter?

A: Measuring the bubble diameter directly with calipers is challenging due to its shape and flexibility, so layflat width provides a more practical measurement for calculating BUR.