1. What is Spindle Speed Calculator?

Definition: This calculator computes the spindle speed (\( N_s \)) in rpm and the feed rate (\( F_r \)) in m/min for a machining operation, such as milling, based on the workpiece diameter, cutting speed, number of teeth, and feed per tooth.

Purpose: It helps machinists optimize the spindle speed and feed rate to achieve efficient material removal while maintaining tool life and surface finish.

2. How Does the Calculator Work?

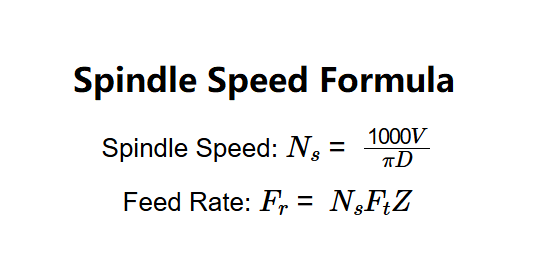

The calculator uses the following equations:

- Spindle Speed: \( N_s = \frac{1000V}{\pi D} \)

- Feed Rate: \( F_r = N_s F_t Z \)

Where:

- \( D \): Diameter of the workpiece (converted to mm);

- \( V \): Cutting speed (converted to m/min);

- \( F_t \): Feed per tooth (converted to mm);

- \( Z \): Number of teeth;

- \( N_s \): Spindle speed (rpm);

- \( F_r \): Feed rate (converted to selected unit: m/min, m/s, ft/min, in/min, mm/min, cm/s).

Steps:

- Enter the diameter of the part and select its unit (mm, cm, m, in, ft).

- Enter the cutting speed and select its unit (m/min, m/s, ft/min, in/min, mm/min, cm/s).

- Enter the number of teeth on the tool.

- Enter the feed per tooth and select its unit (mm, cm, m, in, ft).

- Click "Calculate" to compute the spindle speed and feed rate.

- Select the desired unit for the feed rate.

- Results are displayed with 4 decimal places or in scientific notation if less than 0.001.

3. Importance of Spindle Speed Calculation

Calculating spindle speed and feed rate is crucial for:

- Efficiency: Optimizes machining speed for faster production without compromising quality.

- Tool Life: Prevents excessive wear by ensuring the spindle speed matches the material and cutting conditions.

- Surface Finish: Balances speed and feed to achieve the desired surface quality on the workpiece.

4. Using the Calculator

Example 1: Calculate the spindle speed and feed rate for a milling operation:

- Diameter of Part: 50 mm;

- Cutting Speed: 100 m/min;

- Number of Teeth: 4;

- Feed per Tooth: 0.1 mm;

- Spindle Speed: \( N_s = \frac{1000 \times 100}{\pi \times 50} \approx 636.6198 \, \text{rpm} \);

- Feed Rate: \( F_r = 636.6198 \times 0.1 \times 4 = 254.6479 \, \text{mm/min} \);

- In m/min: \( 254.6479 \times 0.001 = 0.2546 \, \text{m/min} \);

- Result: Spindle Speed = 636.6198 rpm, Feed Rate = 0.2546 m/min.

Example 2: Calculate the spindle speed and feed rate for a different setup:

- Diameter of Part: 2 in (50.8 mm);

- Cutting Speed: 200 ft/min (60.96 m/min);

- Number of Teeth: 6;

- Feed per Tooth: 0.005 in (0.127 mm);

- Spindle Speed: \( N_s = \frac{1000 \times 60.96}{\pi \times 50.8} \approx 382.1596 \, \text{rpm} \);

- Feed Rate: \( F_r = 382.1596 \times 0.127 \times 6 \approx 291.2896 \, \text{mm/min} \);

- In ft/min: \( 291.2896 \times 0.00328084 \approx 0.9557 \, \text{ft/min} \);

- Result: Spindle Speed = 382.1596 rpm, Feed Rate = 0.9557 ft/min.

5. Frequently Asked Questions (FAQ)

Q: What is Spindle Speed?

A: Spindle speed (\( N_s \)) is the rotational speed of the tool or workpiece in rpm, critical for determining how fast the material is cut during machining.

Q: Why is feed rate important?

A: Feed rate (\( F_r \)) determines the speed at which the tool advances into the material, affecting machining efficiency, tool life, and surface finish.

Q: Can this calculator be used for all machining operations?

A: Yes, it can be used for operations like milling, turning, or drilling, as long as the inputs (diameter, cutting speed, etc.) are appropriate for the operation.

Spindle Speed Calculator© - All Rights Reserved 2025

Home

Home

Back

Back