1. What is Pitch Diameter Calculator?

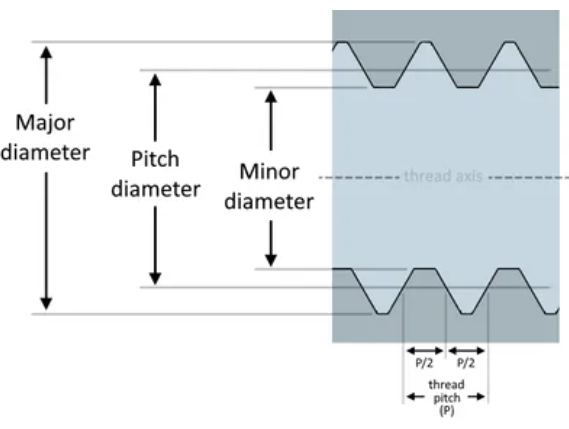

Definition: This calculator computes the pitch diameter of ISO metric screw threads (60° angle), which is the diameter where the thread thickness equals the space between threads. It provides the basic, maximum, and minimum pitch diameters for external threads.

Purpose: It helps engineers and machinists ensure proper fit between bolts and nuts by calculating the pitch diameter, essential for thread design and manufacturing.

2. How Does the Calculator Work?

The calculator uses the following equations:

- Basic Pitch Diameter: \( D_2 = D - 0.6495 \times P \)

- Maximum Pitch Diameter: \( D_{2\text{max}} = D_2 + \text{Fundamental Deviation} \)

- Minimum Pitch Diameter: \( D_{2\text{min}} = D_{2\text{max}} - \text{Tolerance} \)

Where:

- \( D \): Major diameter (mm);

- \( P \): Thread pitch (mm);

- Fundamental Deviation: Depends on tolerance position (e, f, g, h);

- Tolerance: Depends on tolerance grade (\( n \)) and scaled by \( k \) from the table below;

- All results are in mm.

Tolerance Grade Scaling Factors

| \( n \) |

\( k \) |

for \( Td2(n) \) |

for \( TD2(n) \) |

| 3 |

0.50 |

— |

— |

| 4 |

0.63 |

0.85 |

— |

| 5 |

0.80 |

1.06 |

— |

| 6 |

1.00 |

1.32 |

— |

| 7 |

1.25 |

1.70 |

— |

| 8 |

1.60 |

2.12 |

— |

| 9 |

2.00 |

— |

— |

Notes:

- \( n \): Tolerance grade;

- \( k \): Scaling factor used to calculate the pitch diameter tolerance;

- \( Td2(n) \): Scaling factor for external thread pitch diameter tolerance;

- \( TD2(n) \): Scaling factor for internal thread pitch diameter tolerance (not used in this calculator);

- — indicates the value is not applicable for the grade.

Steps:

- Enter the major diameter in mm.

- Select the thread pitch from the dropdown or enter a custom value.

- Select the tolerance grade (\( n \)) from 3 to 9 or enter a custom grade.

- Select the tolerance position (e, f, g, h).

- Click "Calculate" to compute the pitch diameters.

- Results are displayed with 4 decimal places or in scientific notation if less than 0.001.

3. Importance of Pitch Diameter Calculation

Calculating pitch diameter is crucial for:

- Fit and Compatibility: Ensures bolts and nuts mate properly without being too loose or too tight.

- Manufacturing Precision: Helps in machining threads to meet ISO standards.

- Design Optimization: Allows for proper tolerance adjustments based on application needs.

4. Using the Calculator

Example 1: Calculate the pitch diameter for an M20 bolt with a 1.5 mm pitch (6g tolerance):

- Major Diameter: 20 mm;

- Thread Pitch: 1.5 mm;

- Tolerance Grade (\( n \)): 6;

- Tolerance Position: g;

- Basic Pitch Diameter: \( D_2 = 20 - 0.6495 \times 1.5 = 20 - 0.97425 = 19.0258 \, \text{mm} \);

- Fundamental Deviation (g, approx): \( -0.034 \times \sqrt{1.5} \approx -0.0416 \, \text{mm} \);

- Tolerance (Grade 6, \( k = 1.00 \), approx): \( 0.060 \times \sqrt{1.5} \times 1.00 \approx 0.0735 \, \text{mm} \);

- Maximum Pitch Diameter: \( 19.0258 - 0.0416 = 18.9842 \, \text{mm} \);

- Minimum Pitch Diameter: \( 18.9842 - 0.0735 = 18.9107 \, \text{mm} \);

- Result: Basic = 19.0258 mm, Max = 18.9842 mm, Min = 18.9107 mm.

Example 2: Calculate the pitch diameter for an M10 bolt with a custom 0.9 mm pitch (4h tolerance):

- Major Diameter: 10 mm;

- Thread Pitch: 0.9 mm;

- Tolerance Grade (\( n \)): 4;

- Tolerance Position: h;

- Basic Pitch Diameter: \( D_2 = 10 - 0.6495 \times 0.9 = 10 - 0.58455 = 9.4155 \, \text{mm} \);

- Fundamental Deviation (h): 0 mm;

- Tolerance (Grade 4, \( k = 0.63 \), approx): \( 0.060 \times \sqrt{0.9} \times 0.63 \approx 0.0299 \, \text{mm} \);

- Maximum Pitch Diameter: \( 9.4155 + 0 = 9.4155 \, \text{mm} \);

- Minimum Pitch Diameter: \( 9.4155 - 0.0299 = 9.3856 \, \text{mm} \);

- Result: Basic = 9.4155 mm, Max = 9.4155 mm, Min = 9.3856 mm.

5. Frequently Asked Questions (FAQ)

Q: What is Pitch Diameter?

A: Pitch diameter is the diameter of an imaginary cylinder where the thread thickness equals the space between threads, critical for thread fit.

Q: What do tolerance grade and position mean?

A: Tolerance grade (\( n \), 3 to 9) defines the precision of the thread, with lower numbers indicating tighter tolerances. Tolerance position (e, f, g, h) determines the fundamental deviation, affecting how loose or tight the thread fit is (h means zero deviation, e means a looser fit).

Q: Can this calculator be used for non-metric threads?

A: No, this calculator is designed for ISO metric screw threads (60° angle) only.

Pitch Diameter Calculator© - All Rights Reserved 2025

Home

Home

Back

Back