1. What is Material Removal Rate Calculator?

Definition: This calculator computes the Material Removal Rate (MRR), which is the volume of material removed per unit time during machining operations such as turning, drilling, milling, grinding, and grooving.

Purpose: It assists users in manufacturing by determining how efficiently material is being removed, helping to optimize machining parameters, reduce production time, and improve productivity.

2. How Does the Calculator Work?

The calculator uses the following equations based on the machining operation:

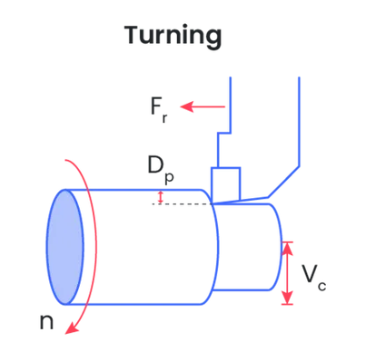

- Turning: \( \text{MRR} = D \times F_r \times V_c \)

- Drilling: \( \text{MRR} = \frac{1}{4} \times D \times F_r \times V_c \)

- Milling: \( \text{MRR} = D_p \times D_r \times V_f \)

- Grinding: \( \text{MRR} = D \times W \times V_f \)

- Grooving: \( \text{MRR} = W \times F_r \times V_c \)

Where:

- \( D \): Depth of cut (mm);

- \( F_r \): Feed rate (converted to mm/rev for turning, drilling, and grooving; mm/min for milling and grinding);

- \( V_c \): Cutting speed (converted to mm/min for calculation);

- \( D_p \), \( D_r \): Depth and width of cut for milling (mm);

- \( V_f \): Feed velocity (converted to mm/min for calculation);

- \( W \): Width of cut (mm);

- MRR is initially calculated in mm³/min, then converted to the selected unit (mm³/min, mm³/s, cm³/s, cm³/min, in³/min, in³/s, m³/min, m³/s, ft³/min, ft³/s).

Steps:

- Select the machining operation (turning, drilling, milling, grinding, grooving).

- Enter the required parameters for the selected operation (e.g., depth of cut, feed rate, cutting speed) and their units.

- Click the "Calculate" button to compute the MRR.

- Convert all measurements to millimeters.

- Calculate the MRR using the appropriate formula.

- Convert the MRR to the selected output unit.

- Display the result, formatted in scientific notation if the absolute value is less than 0.001, otherwise with 4 decimal places.

3. Importance of Material Removal Rate Calculation

Calculating MRR is crucial for:

- Productivity: Measures how efficiently material is removed, directly impacting production time and costs.

- Process Optimization: Helps adjust machining parameters to maximize efficiency while maintaining quality.

- Tool Life: Balances removal rates with tool wear to ensure longevity and cost-effectiveness.

4. Using the Calculator

Example 1 (Drilling with New Unit): Calculate the MRR for a drilling operation:

- Drill Diameter: 1 mm;

- Feed Rate: 0.5 cm/rev;

- Cutting Speed: 12 m/s;

- Convert \( D \): \( 1 \, \text{mm} \);

- Convert \( F_r \): \( 0.5 \times 10 = 5 \, \text{mm/rev} \);

- Convert \( V_c \): \( 12 \times 1000 \times 60 = 720000 \, \text{mm/min} \);

- MRR: \( \text{MRR} = \frac{1}{4} \times 1 \times 5 \times 720000 \);

- \( \text{MRR} = \frac{1}{4} \times 1 \times 5 \times 720000 = 900000 \, \text{mm}^3/\text{min} \);

- Convert to ft³/s: \( (900000 \div 28316846.592) \div 60 \approx 0.0005297 \, \text{ft}^3/\text{s} \);

- Result: MRR = 900000.0000 mm³/min or 5.2972e-4 ft³/s.

Example 2 (Grooving with New Unit): Calculate the MRR for a grooving operation:

- Width of Cut: 0.25 in;

- Feed Rate: 0.2 in/rev;

- Cutting Speed: 100 ft/min;

- Convert \( W \): \( 0.25 \times 25.4 = 6.35 \, \text{mm} \);

- Convert \( F_r \): \( 0.2 \times 25.4 = 5.08 \, \text{mm/rev} \);

- Convert \( V_c \): \( 100 \times 304.8 = 30480 \, \text{mm/min} \);

- MRR: \( \text{MRR} = W \times F_r \times V_c \);

- \( \text{MRR} = 6.35 \times 5.08 \times 30480 \approx 983349.84 \, \text{mm}^3/\text{min} \);

- Convert to ft³/min: \( 983349.84 \div 28316846.592 \approx 0.0347 \, \text{ft}^3/\text{min} \);

- Result: MRR = 983349.8400 mm³/min or 0.0347 ft³/min.

5. Frequently Asked Questions (FAQ)

Q: What is Material Removal Rate (MRR)?

A: MRR is the volume of material removed per unit time during a machining process, typically measured in units like mm³/min, cm³/s, in³/min, or ft³/s.

Q: Why does the calculator convert all units to millimeters?

A: Using a consistent unit (mm) ensures accurate calculations across different machining operations, as most machining formulas are standardized in metric units.

Q: How can I optimize MRR?

A: Increase depth of cut, feed rate, or cutting speed, but balance these with tool life, surface finish, and machine capabilities to avoid excessive wear or damage.

Q: Why does the drilling formula not include \( \pi \)?

A: The provided formula for drilling (\( \text{MRR} = \frac{1}{4} \times D \times F_r \times V_c \)) follows the source specification. However, the standard formula includes \( \pi \) (\( \text{MRR} = \frac{\pi}{4} \times D^2 \times F_r \times V_c \)) to account for the circular cross-section of the hole. This calculator uses the provided formula as specified.

Material Removal Rate Calculator© - All Rights Reserved 2025

Home

Home

Back

Back