1. What is the Bolt Torque Calculator?

Definition: This calculator estimates the torque required to achieve a specific clamping force for a bolt, based on the bolt’s material, diameter, lubrication, and a constant factor \( K \).

Purpose: It assists engineers, mechanics, and DIY enthusiasts in determining the appropriate torque to apply when tightening bolts, ensuring secure fastening without over-tightening or damaging components.

2. How Does the Calculator Work?

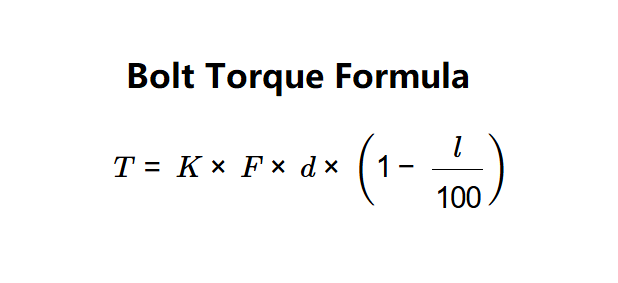

The calculator uses the following equation:

- \[ T = K \times F \times d \times \left(1 - \frac{l}{100}\right) \]

Where:

- \( T \): Torque (N·m, kgf·cm, J/rad, lbf·ft, or lbf·in);

- \( K \): Constant factor based on bolt material and finish (e.g., 0.2 for mild-steel, dry);

- \( F \): Clamping force (N or lbf);

- \( d \): Bolt diameter (mm, cm, m, in, or ft);

- \( l \): Lubrication percentage (%).

Steps:

- Enter the clamping force and select its unit (N or lbf).

- Enter the bolt diameter and select its unit (mm, cm, m, in, or ft).

- Select a lubricant (e.g., Graphite) or choose custom and enter a lubrication percentage (0-100).

- Select a bolt type (e.g., mild-steel, dry) or choose custom and enter a \( K \) factor.

- Convert inputs to metric units (N for force, m for diameter).

- Calculate torque in N·m using the formula.

- Convert torque to the selected output unit (N·m, kgf·cm, J/rad, lbf·ft, or lbf·in).

- Display the result, formatted in scientific notation if the absolute value is less than 0.001, otherwise with 4 decimal places.

3. Importance of Bolt Torque Calculation

Calculating the correct bolt torque is crucial for:

- Safety: Ensures bolts are tightened to hold components securely without failure.

- Durability: Prevents over-tightening, which can damage bolts or threads, or under-tightening, which can cause loosening.

- Precision: Accounts for material, lubrication, and size to achieve the desired clamping force.

- Efficiency: Optimizes assembly processes in engineering and construction.

4. Using the Calculator

Example 1 (Metric Units): Calculate the torque with metric units and Graphite lubricant:

- Clamping Force: \( F = 10000 \, \text{N} \);

- Bolt Diameter: \( d = 12 \, \text{mm} \);

- Lubricant: Graphite (\( l = 52.5\% \));

- Bolt Type: Mild-steel, lubricated (\( K = 0.18 \));

- Output Unit: Newton meters;

- Torque: \( T = 0.18 \times 10000 \times 0.012 \times (1 - 0.525) = 10.26 \, \text{N·m} \);

- Result: \( T = 10.2600 \, \text{N·m} \).

Example 2 (Imperial Units, Custom Lubrication): Calculate the torque with imperial units and custom lubrication:

- Clamping Force: \( F = 2000 \, \text{lbf} \);

- Bolt Diameter: \( d = 0.5 \, \text{in} \);

- Lubricant: Custom (\( l = 30\% \));

- Bolt Type: Custom (\( K = 0.25 \));

- Output Unit: Pound-force inches;

- Force: \( 2000 \times 4.44822 = 8896.44 \, \text{N} \);

- Diameter: \( 0.5 \times 0.0254 = 0.0127 \, \text{m} \);

- Torque: \( 0.25 \times 8896.44 \times 0.0127 \times (1 - 0.3) \approx 19.7697 \, \text{N·m} \times 8.85075 \approx 175.0047 \, \text{lbf·in} \);

- Result: \( T = 175.0047 \, \text{lbf·in} \).

5. Frequently Asked Questions (FAQ)

Q: Why does the K factor vary?

A: The \( K \) factor depends on the bolt’s material and surface finish (e.g., dry, lubricated, or plated), affecting friction during tightening. Common values range from 0.1 to 0.3.

Q: How do lubricants affect torque?

A: Lubricants like Graphite or SAE oils reduce friction, lowering the torque needed. Predefined percentages (e.g., 52.5% for Graphite) reflect typical friction reduction; custom values allow flexibility.

Q: Can I use this for non-mild-steel bolts?

A: Yes, select the custom option and enter the appropriate \( K \) factor for your bolt material (e.g., stainless steel may have \( K \approx 0.2 \)).

Home

Home

Back

Back